Product Specification

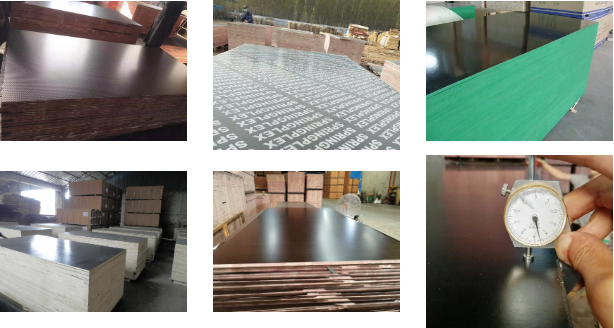

Name: Hot Sale Cheaper Phenolic Glue Brown Film Face Plywood

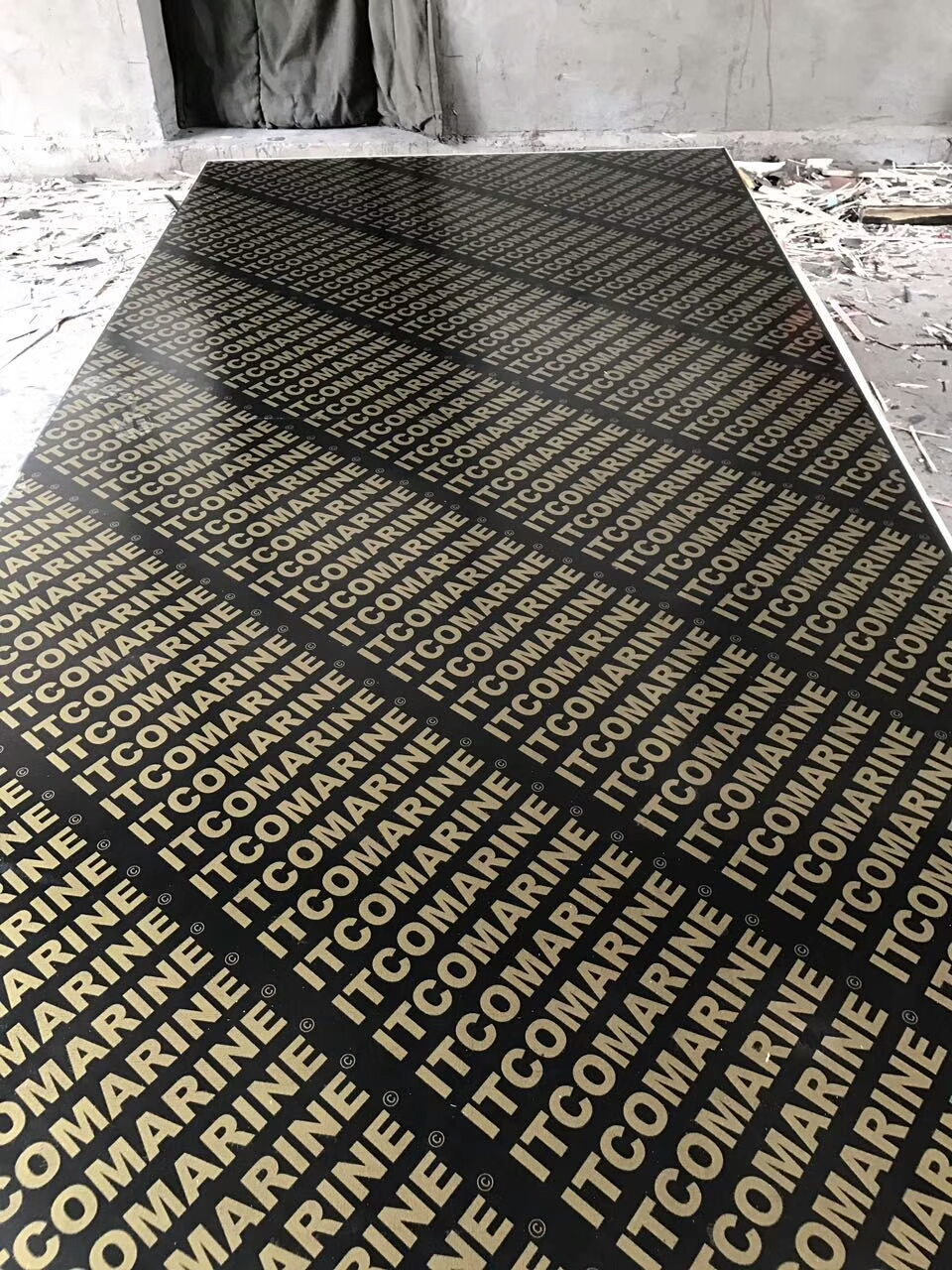

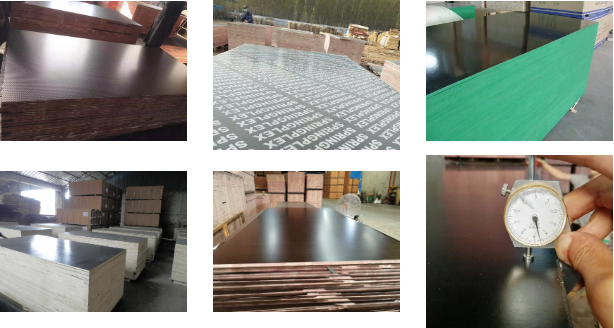

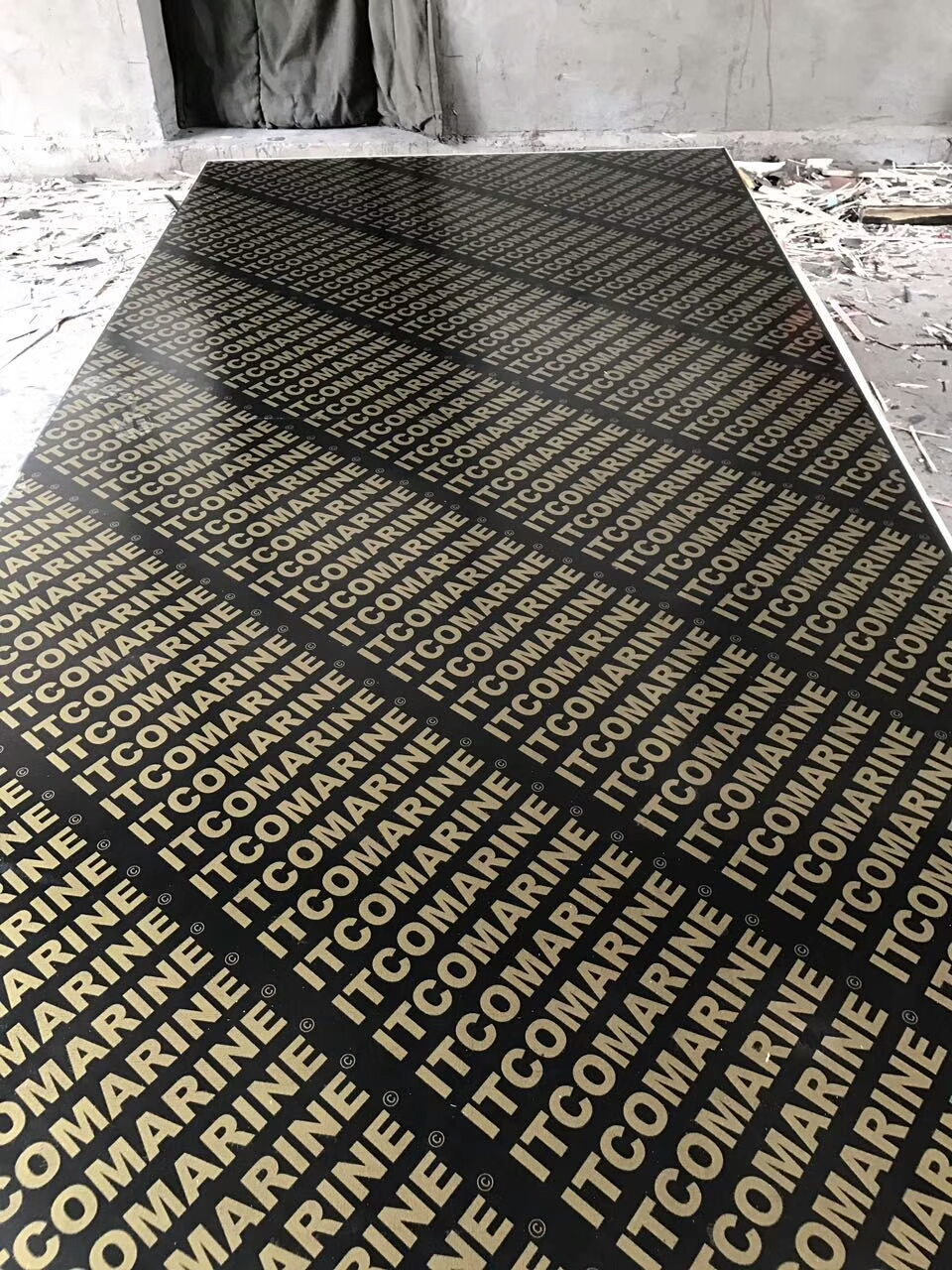

Film: brown film, black film, brown film,red film ...

Core :birch, poplar, eucalyptus, hardwood, comb i wood ..

Size :1220*2440mm,1250*2500mm,915*1830mm, 1200*2700mm ...

Thickness : 4mm-30mm

Tolerance o f Thickness :+/-0.2mm for 4mm, 5mm, 6mm ...

+/-0.5mm for thick plywood

Length(Width) Tolerance: +/-0.2mm

Edge sealed with waterproof paint

Moisture Content: less than 12%

Density of Plywood: 540-680kg/m3

Modulus of Rupture :more than 30mpa

Modulus of Elasticity : more than 6000mpa

Usage: Used for construction, building house, flooring, shopping mall

Payment Term: L/C, T/T, D/P

Delivery :12-15 days

Package :standard exporting package( bottom is pallet, covered with plastic film,

around is carton,strengthen by steel tape with 3*6 )

Product Description

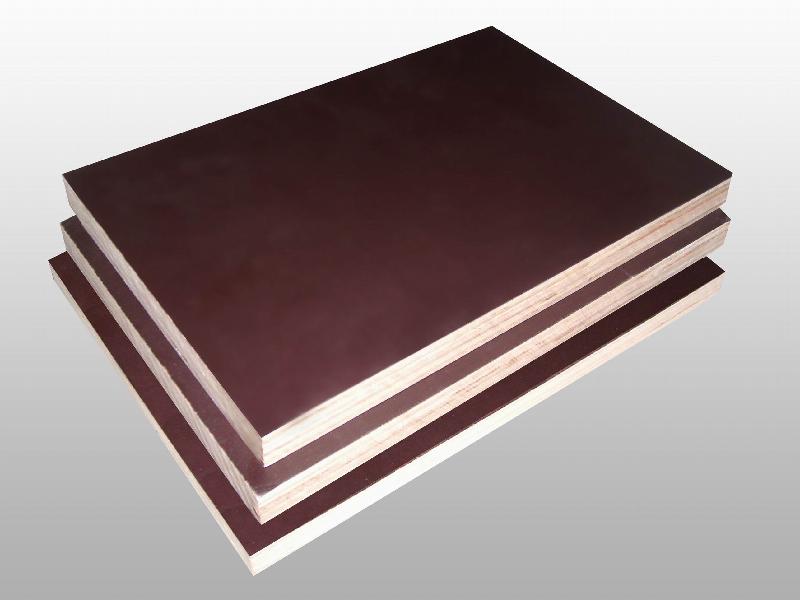

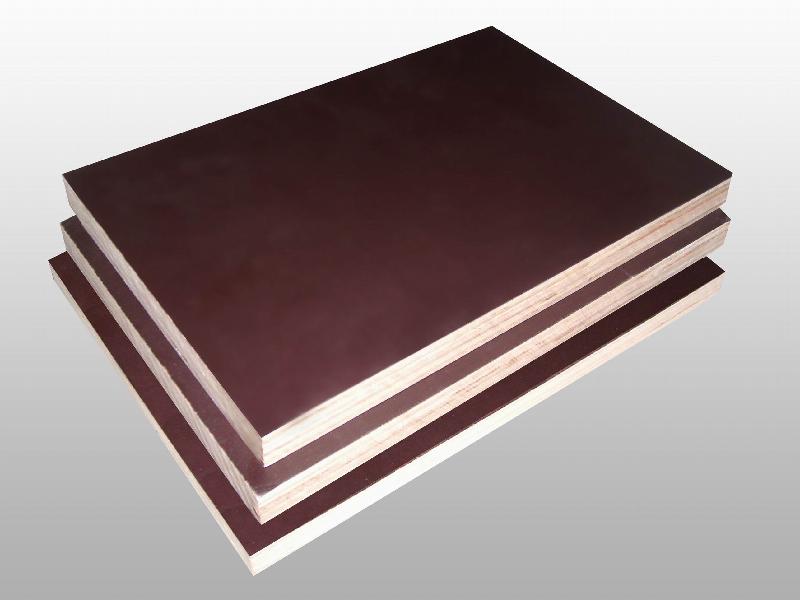

This Film Faced Plywood is designed for demanding construction environments. Made with phenolic glue and featuring a brown film surface, it offers superior durability, moisture resistance, and a smooth finish. With lightweight cores such as eucalyptus and poplar, this plywood is easy to handle and cut. It is ideal for use in slabs, columns, beams, and more, ensuring strength and efficiency on-site.

Exceptional Strength and Durability

Our Phenolic Glue Brown Film Face Plywood offers superior resistance to wear, cracking, and harsh conditions like acids and alkalis. This makes it highly suitable for construction plywood applications, especially in concrete formwork. The film faced plywood features a smooth and hard surface that delivers a clean and even finish, reducing the need for secondary plastering. Thanks to its high modulus of rupture (>30 MPa) and modulus of elasticity (>6000 MPa), it can withstand the stresses of concrete placement and curing.

Lightweight and Easy to Handle

Crafted from premium materials like eucalyptus plywood and poplar core plywood, it is lightweight and easy to transport and cut. Workers can handle single formwork panels without extra equipment, making it ideal for fast-paced construction environments. The film faced plywood comes in a variety of sizes, including 1220x2440mm and 1250x2500mm, with thickness ranging from 4mm to 30mm.

Multi-functional and Reusable

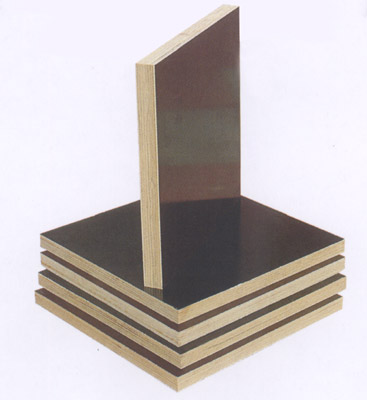

This reusable plywood can be repurposed up to 15 times, offering significant cost savings compared to metal formwork. It performs exceptionally well under various temperature conditions, from -40°C to +50°C, without deforming. Moreover, the high-quality film used on the surface protects against corrosion, moisture, and other environmental factors, further enhancing its durability and extending its life cycle.

Product Features

Waterproof and Durable: The phenolic glue plywood is sealed with waterproof paint on the edges, preventing water absorption and ensuring durability. Its wear-resistant plywood surface can withstand heavy use in construction environments.

High Strength and Stability: Made from high-grade eucalyptus and poplar cores, the high strength plywood offers superior structural integrity, ensuring stability in demanding applications. With a modulus of rupture greater than 30MPa, this construction plywood is built to last.

Smooth Surface: Coated with brown film plywood or black film plywood, the surface is exceptionally smooth, providing a superior finish that reduces the need for extra plastering. This makes it ideal for concrete formwork plywood in construction projects.

Reusable and Cost-Efficient: The reusable plywood can be repurposed up to 15 times, making it a cost-effective solution for contractors. It reduces material waste and minimizes construction costs.

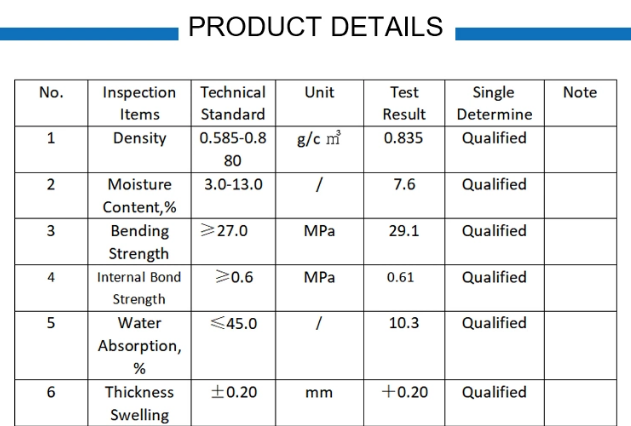

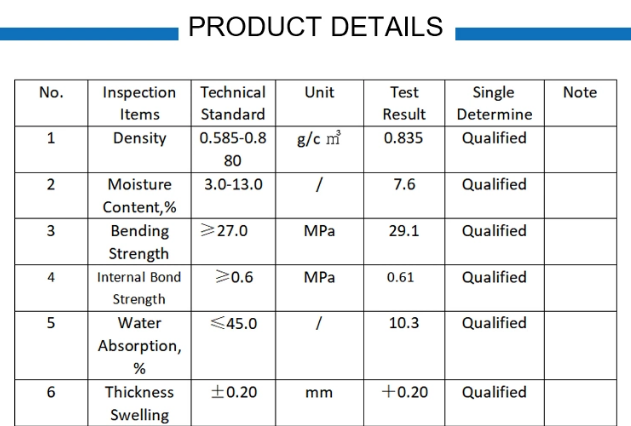

Product Details:

Application Introduction

Wear-Resistant and Anti-Cracking: The film faced plywood is designed to resist wear, cracking, and corrosion, including resistance to acids and alkalis, making it ideal for harsh construction environments.

Lightweight for Easy Handling: Made from eucalyptus plywood and poplar core plywood, this product is lightweight, ensuring convenient transport and installation. One person can handle the plywood for walls, beams, slabs, and other construction uses, improving work efficiency.

Easy to Cut and Shape: The plywood for construction can be easily cut to size, allowing it to be tailored for specific formwork needs. Its versatility makes it an excellent choice for projects of all sizes.

Reusable Up to 15 Times: This moisture-proof plywood can be reused multiple times, offering a durable alternative to metal formwork. Its reusability significantly lowers construction costs over time.

No Deformation Under Heat or Moisture: The plywood remains stable and non-deformed even after being submerged in boiling water for 48 hours, demonstrating excellent resistance to heat and moisture—key features of anti-cracking plywood and moisture-proof plywood.

Ideal for Multiple Uses: Whether for columns, beams, slabs, or bridge concrete pouring, this lightweight plywood offers the versatility needed in diverse construction applications, delivering high performance across all tasks.

Raw Materials

![G9$6H5]FDZ_5PBM8K~`YI~S](//ikrorwxhlqnjll5p.ldycdn.com/cloud/lnBpqKmrloSRokjpkqmrjp/G9-6H5-FDZ_5PBM8K-YI-S.png)

How to Maintain

To maintain your film faced plywood, store it in a dry environment away from direct sunlight. Clean the surface after each use to ensure no concrete residue is left behind, and apply waterproof paint to exposed edges if needed.

FAQs

Q: How many times can the plywood be reused?

A: The plywood can be reused up to 15 times under normal conditions.

Q: Is this plywood resistant to chemicals?

A: Yes, the film faced plywood is resistant to acids, alkalis, and other chemicals, making it highly durable for construction applications.

Q: What sizes are available?

A: Common sizes include 1220x2440mm, 1250x2500mm, and custom sizes upon request.

![G9$6H5]FDZ_5PBM8K~`YI~S](http://ikrorwxhlqnjll5p.ldycdn.com/cloud/lnBpqKmrloSRokjpkqmrjp/G9-6H5-FDZ_5PBM8K-YI-S.png)