Product Overview

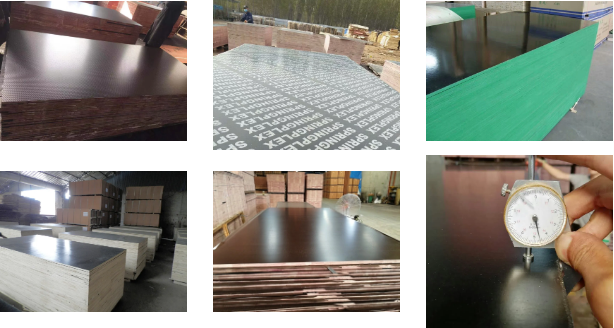

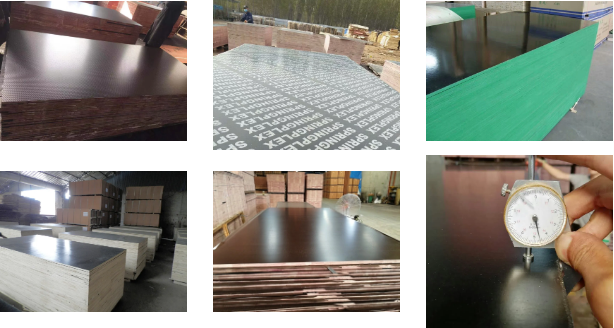

The 4X8 Concrete Construction Form Poplar Formwork Film Face Plywood is an ideal solution for concrete formwork, boasting high strength and durability. Coated with a premium film, this plywood ensures a smooth finish and is resistant to moisture and wear. It's perfect for various construction applications, offering long-lasting reliability. Featuring cores such as poplar and birch, this film-faced plywood is designed for high-performance use, making it a trusted choice in the industry.

1. High-Quality Construction Plywood for Concrete Formwork

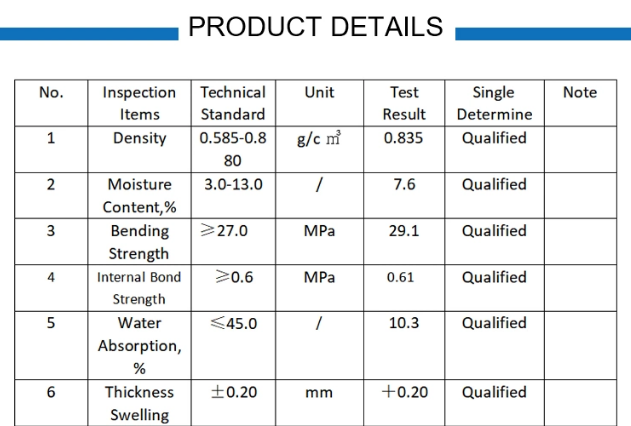

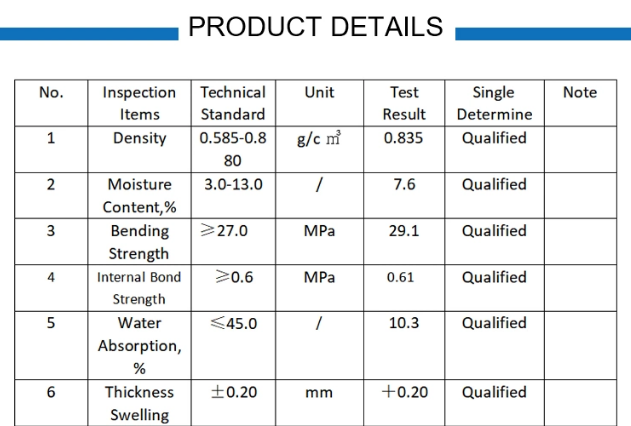

This Film Face Plywood is designed for the rigorous demands of concrete formwork. The brown film finish provides an excellent surface for smooth concrete casting while being moisture-resistant, enhancing durability. The core options, such as poplar, birch, and eucalyptus, provide structural integrity and resistance against warping. This plywood is ideal for large-scale projects, including building houses, flooring, and shopping malls. With a thickness range from 4mm to 30mm, it can withstand heavy loads and stress, providing long-lasting performance.

2. Superior Waterproofing and Durability

The plywood edges are sealed with waterproof paint, ensuring excellent resistance to moisture penetration. This feature makes it highly suitable for outdoor and indoor construction environments, where moisture levels can vary. In addition, with a moisture content of less than 12%, it offers enhanced stability, reducing the risk of swelling or deformation in wet conditions. This ensures long-term reliability for builders and contractors alike.

3. Designed for Heavy-Duty Performance

Built to meet both Chinese and international standards, this film-faced plywood has a Modulus of Rupture of over 30Mpa and a Modulus of Elasticity greater than 6000Mpa. These values indicate superior strength and flexibility, ensuring the plywood can withstand the demands of modern construction. Additionally, its density ranges from 540-680kg/m3, offering the balance of strength and lightweight design needed for efficient handling on-site.

Product Features

Film-Faced Plywood with anti-slip properties for enhanced safety.

High Strength and Durability to withstand heavy loads and stress.

Waterproof and Moisture-Resistant design for long-lasting use in various environments.

Available in multiple core options: poplar, birch, eucalyptus, and hardwood.

Edge Sealed with Waterproof Paint to prevent moisture absorption.

Size Options: 1220x2440mm, 1250x2500mm, 915x1830mm, etc.

Thickness Range: 4mm-30mm with tight tolerance.

Applications

Concrete Formwork: Ideal for creating smooth surfaces in concrete casting projects.

Building Construction: Perfect for flooring, walls, and other structural components.

Commercial Spaces: Suitable for use in shopping malls and large commercial projects due to its durability and strength.

Product Details

Raw Materials

How to Maintain

Storage: Store in a dry, ventilated area away from direct moisture to prolong its life.

Cleaning: Wipe down the surface after use, especially after exposure to concrete, to prevent residue buildup.

Protection: Reapply waterproof sealant on the edges if there are signs of wear or damage.

How to Use

Ensure the surface area where the plywood will be used is clean and level.

Secure the plywood panels using appropriate fasteners for formwork.

Once concrete is poured and set, carefully remove the plywood to avoid surface damage, ensuring its reuse in future projects.

FAQs

Q1: Can this plywood be reused in multiple construction projects?

Yes, with proper care, this film-faced plywood can be reused multiple times in construction projects, particularly for formwork.

Q2: Is the waterproof film resistant to heavy rainfall or constant moisture?

Yes, the film coating and waterproof edge sealant are designed to protect the plywood from heavy moisture and rainfall, making it suitable for outdoor use.

Q3: How does the poplar core compare to birch or eucalyptus cores?

Poplar offers a lighter weight, while birch and eucalyptus provide more strength and density. The choice depends on the specific strength and durability requirements of your project.

This plywood from Huasheng meets the highest standards of performance, making it the ideal solution for construction needs across various industries.